WG 5.0 – Device Testing

- Status:

- Active

- Working Group Chair:

- Brett Carn, Intel

-

-

-

Summary of discussions/activities/document reviews during the most recent WG meeting.

- ATE testing only at the beginning/end of step stressing

- During characterization, ATE may not be used, whereas it's required during qualification. Many use leakage measurements and it was suggested to add guidance in the User Guides for HBM and CDM.

- Action Item: Brett will draft a proposal for WG5 review.

- Use of curve tracing in place of ATE during characterization

- Many use curve tracing during characterization, rather than ATE but there's limited information available on interpreting curve tracing.

- WG decided information is needed and a TR should be developed on curve tracing. A writing team was identified.

- Start as a TR and then discuss as to whether this would be folded into the individual User Guides.

- Action item: Develop a TR highlighting when it’s useful, how to perform, how to avoid causing damage and how to interpret results – Brett to kick off the first call and identify owners.

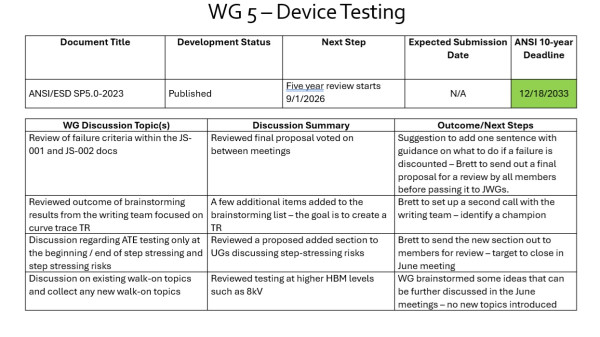

- Review of failure criteria within the JS-001 and JS-002 docs

- Terms are different in the documents and don't really cover all scenarios.

- WG spent time in the meeting to modify the failure criteria – after the final WG review, this will be used in both JS-001 and JS-002.

- Action item: Brett to send out the suggested change options for the failure criteria for WG vote.

- ATE testing only at the beginning/end of step stressing

-

A consensus was reached on adjusting language regarding the interchangeability of CDM units for HBM testing and vice versa—identified text in JS-001 and JS-002 requiring modification or removal. The decision will be forwarded to both JWGs for integration into the upcoming JS-001 and JS-002 updates.

Lengthy discussion on failure criteria in JS-001 and JS-002, exploring the feasibility of offering more guidance. Consideration of a Technical Report (TR) for additional direction, as no further information can be appended to JS-001 and JS-002.

-

The committee held discussions on two important topics affecting both the HBM (Human Body Model) and CDM (Charged Device Model) Joint Working Groups (JWGs):

- Consistency in unit usage for both HBM and CDM tests.

- Implementing step-stressing of units with testing conducted only at the beginning and end.

Statements addressing these topics were developed for use in both JS-001 (HBM) and JS-002 (CDM). A final draft of these statements will be finalized on a virtual call before June.

-

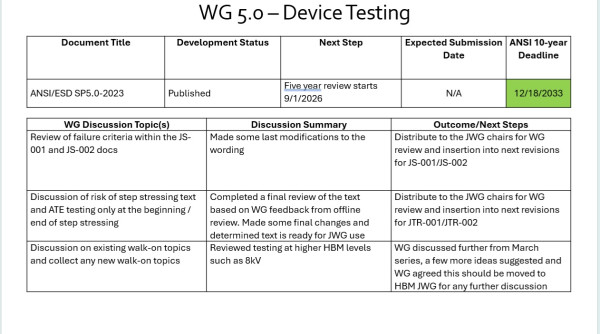

The WG adjudicated the industry review comments on DSP5.0-2023 - “Reporting ESD Withstand Levels on Datasheets”.

-

The WG discussed possible updates to SP5.0 – “Reporting ESD Withstand Levels on Datasheets”.

It was mentioned, that high voltage HBM stress is being performed on select pins on devices. A datasheet was shared, which showed how different HBM testing (levels) done on individual pin sets are reported differently. The question was, does ANSI/ESD SP5.0 need to be updated to include this information?

Another question was asked, should HBM and CDM testing be performed on the same exact units (no ATE in between)?

- General consensus was that latch-up testing cannot be done on units that were HBM/CDM testing.

- HBM and CDM stress on the same exact units is still an open question.

- Details on a product that had ESD field failures but passed HBM and CDM qualification levels were shared with the group.

- Open discussion on exploring alternative stress methods to re-create the damage occurring in the field. The product was featured in a 2011 Symposium paper.

-

The WG addressed final TAS comments on WIP5.0 – “Reporting ESD Withstand Levels on Datasheets”. The document is ready for STDCOM submission.

-

The group completed the five-year review of ANSI/ESD SP5.0. There was also a discussion on how die-to-die interfaces are handled regarding ESD targets and testing.