WG 15.0 – Gloves

- Status:

- Active

- Working Group Chair:

- Robert Vermillion, RMV Technology Group, LLC

-

-

-

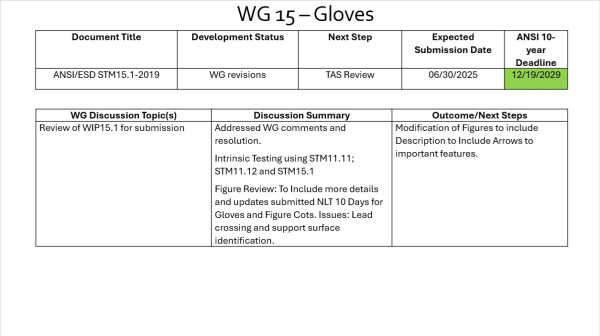

Summary of discussions/activities/document reviews during the most recent WG meeting.

- Focused on the 5-year review of ANSI/ESD STM15.1.

- Review has been completed through the main body of the document and the next meeting will focus on completing the Annex reviews.

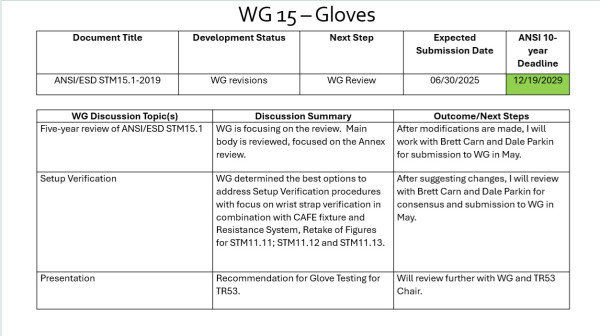

- Discussion in the meeting on options to verify the setup before starting testing. WG will need to determine the best options to address this and add it to WIP15.1 as part of this update.

-

The group continued the five-year review of ANSI/ESD STM15.1.

-

The group started the five-year review of ANSI/ESD STM15.1.

-

A presentation on the Limits for Gloves was given. The WG reviewed the industry survey, which showed that it was overwhelmingly in favor of limits, with several additional comments on the need for charging limits. There was a lively discussion on the limits and the importance of them. Also, the importance of triboelectrification or charge generation to prevent CDM and other various test methods was discussed.

-

The committee discussed the reasons for using two-cylinder electrodes for compliance verification within the EPA:

- Measures operators wearing gloves using two stainless steel cylinders that are cleaned with IPA 70%.

- Affords measuring both types of gloves that are conductive or static dissipative.

- Method is not a replacement when a wriststrap is worn on one hand, and the other hand holds the stainless steel cylinder.

Two members are moving forward on investigating the breakdown voltage for ESD safe gloves.

There was a long discussion on proposing limits for gloves in ANSI/ESD S20.20 using ANSI/ESD STM15.1. The WG discussed defining different guideline recommendations with various glove types. A survey will be conducted with predetermined questions to end users and glove suppliers to address why is there no glove resistance limits in ANSI/ESD S20.20.

-

The WG reviewed a new proposed TR “ESD Gloves and Finger Cots” Test Methods. Triboelectrification was also discussed as well as shielding of gloves versus CAFE resistance.

-

Discuss feedback on conducting Various Test Methods for WG15 TR “ESD Glove and Finger Cots” implementation that could cross over to TR53 “Compliance Verification of ESD Protective Equipment and Materials”.

An Ad Hoc Team was formed, and an Ad Hoc Meeting (sidebar) will take place in Mid May 2022 to discuss this further.

-

The working group discussed establishing a limit for ESD glove qualification based on industry input and possible new technical report activities on other topics.

-

The WG continued discussions on industry test methods for triboelectrification testing for gloves.

-

A presentation was given on various testing methods. A task team will begin working on compiling test methods for triboelectrification testing, resistance verification, breakdown voltage, decay, and charge retention.

-

Summary of meeting activities:

The group reviewed industry acceptance of the newly released ANSI/ESD STM15.1-2019. A decision was made to table discussion on charge retention. There was also a review of several electrostatic decay testing methods currently being utilized in industry using a 1” x 1” charge plate, 3.25” x 3.25” charge plate and 6” x 6” charge plate to verify glove performance during audits and assessments along with using the CAFE fixture with a charge plate for decay measurements. WG15 efforts will focus on compliance verification not qualification testing for a future technical report incorporating such methods and more.