WG 17.0 – Process Assessment

- Status:

- Active

- Working Group Chair:

- Co-Chairs: Wolfgang Stadler, Intel Germany Services GmbH; Reinhold Gaertner, Infineon Technologies AG

-

- Welcome (2 minutes)

- Assign a note-taker to capture the meeting minutes (2 minutes)

- Review Etiquette and Policies Slides (1-3 minutes)

- Document Status (5 minutes):

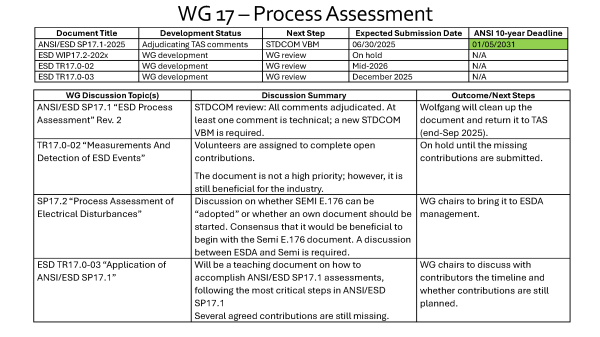

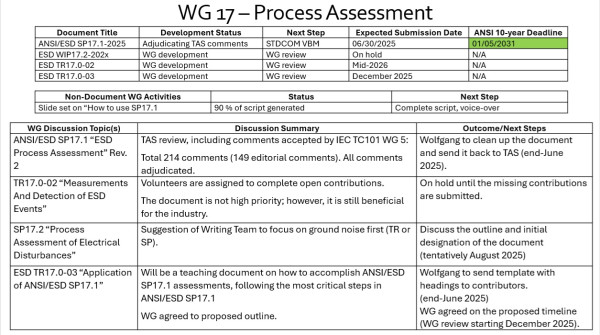

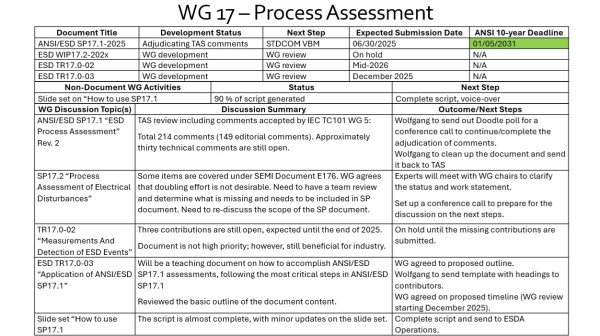

Document Title

Development Status

Next Step

Expected Submission Date

ANSI 10-Year Deadline

ANSI/ESD SP17.1

“Process Assessment Techniques”In Industry Review

Adjudicate comments from IR

End-March 2026

December 2030

ANSI/ESD SP17.2

“Electrical Disturbances”Development started

WG review

End-2026 to

mid-2027n/a

ESD TR17.0-02

“ESD Event Detection”

Development started

WG review

End-2026

n/a

ESD TR17.0-03

“Handbook”

Development started

WG review

End-2026

n/a

5. Brief status update of TR17.0-02 “Measurements and Detection of ESD Events” (former SP10.2) – 10 minutes [Wolfgang]

– Intended outcome: Update timeline and assign remaining sections to WG members6. Next steps on SP17.2 “Process Assessment of Electrical Disturbances”– 10 minutes [Friedrich]

– Intended outcome: Finalize outline, assign sections to volunteers, assign timeline7. Next revision of ANSI/ESD SP17.1 “ESD Process Assessment” – 50 minutes [Wolfgang]

– Intended outcome: Complete adjudication of Industry Review comments and prepare the document for publication8. Technical Report on Application of ANSI/ESD SP17.1 to process steps, including die-to-die interfaces with very low ESD sensitivity – 30 minutes [Friedrich]

– Intended outcome: Discuss sections with examples of processes; timeline until completion of first draft for WG review

9. Assigned Action Items [5 minutes]

10. Review of parking lot items [5 minutes]

11. Other Business**

12. Schedule the next meeting

-

-

-

-

Summary of discussions/activities/document reviews during the most recent WG meeting.

- ANSI/ESD SP17.1 Rev. 2:

- Discussion of TAS review including comments accepted by IEC TC101 WG5, total 214 comments

- 12 comments completed, further adjudication in virtual meetings

- Slide set “How to use SP17.1” completed, next step: create script

- ANSI/ESD SP17.2 “Process Assessment of Electrical Disturbances”:

- Some items are covered under SEMI Document E176. WG agrees that doubling effort is not desirable.

- Need to re-discuss the scope and contents of the SP document.

- Technical Report on Application of ANSI/ESD SP17.1:

- Will be a teaching document on how to accomplish ANSI/ESD SP17.1 assessments

- Reviewed and agreed on the basic outline of the document content

- Document timeline: Inputs due by end of January 2025

- TR17.0-02 “Measurements And Detection of ESD Events”: currently on hold

- ANSI/ESD SP17.1 Rev. 2:

-

During the meeting, the working group (WG) decided on the introduction slide set for ANSI/ESD SP17.1. Additionally, they deliberated on the feasibility of a new standard practice (SP) focused on "Process Assessment of Electrical Disturbances," distinguishing it from SEMI E178, and explored potential collaborations. It was suggested that the scope of the SP should be narrowed down. A final decision regarding the document and its scope is scheduled for the September meeting. Furthermore, the WG discussed potential topics for a new technical report (TR) concerning the application of SP17.1 to process assessments in various contexts, such as process steps involving die-to-die interfaces, and volunteers were assigned for further exploration.

-

The committee adjudicated comments in ANSI/ESD SP17.1 Rev. 2 from the final WG review; one technical concern remains, which requires clarification.

-

The WG reviewed the final proposed technical changes in ANSI/ESD SP17.1 Rev. 2. Approach for determination of “contact resistance” was decided on. A presentation was given on alternative risk assessment methods of printed circuit boards (PCBs). Results could be added in future revision of ANSI/ESD SP17.1.

-

The WG reviewed the status and next steps of ESD WIP17.2 and introductory slide sets. The WG agreed to start work on another technical report focusing on the application of flow and methods of ANSI/ESD SP17.1 to process steps with die-to-die interfaces. A presentation was given on CDM discharge measurements in process equipment. The approach would be beneficial for ANSI/ESD SP17.1 assessment flows, so work will continue.

-

The WG discussed updates and remaining open technical changes to ANSI/ESD SP17.1 Rev. 2. Document is to be updated for the first WG review until May 2023. A draft of the slide set on “How to use SP17.1” was presented, content modifications discussed and agreed on, and work will continue on this effort between meetings and discussed in virtual meetings if required.

-

The WG discussed comments from IEC TC101 review on the committee draft (CD) of IEC/TS 61340-5-6 (IEC version of ANSI/ESD SP17.1). The discussion turned to whether these comments should be included in ANSI/ESD SP17.1 Rev. 2. A presentation was given on measurements of contact resistances of several different materials, showing the DC resistance and resistance under ESD conditions can be significantly different. The study is relevant for objects contacting ESDS items. Results will have an impact on almost all ESD process assessment flows in ANSI/ESD SP17.1. A writing team was established to review and incorporate this information.

-

The WG had a discussion on topics of ANSI/ESD SP17.1 “ESD Process Assessment Methodologies in Electronic Production Lines – Best Practices used in Industry” for Revision 2 which is ongoing.

Subjects like bandwidth of oscilloscopes and estimation of CDM peak currents based on product capacitances were discussed. Members felt that the capacitance values should be based on information in ANSI/ESDA/JEDEC JS-002 and discussion and studies within the CDM JWG.

-

The WG had a discussion on topics of SP17.1 “ESD Process Assessment Methodologies in Electronic Production Lines – Best Practices used in Industry” for Revision 2 which is ongoing. WG agreed on proposed new flow descriptions of process assessment. Equipment grounding Sections of ANSI/ESD SP10.1 “Measurement and ESD Control Issues for Automated Equipment Handling of ESD Sensitive Devices Below 100 Volts” will be included in SP17.1 Revision 2.

An outline of SP17.2 “Process Assessment of Electrical Disturbances” was presented; designation as TR or SP is still open; will have a similar structure as TR17.0-01 (explain methodology, measurements, and assessment by means of published examples).

ANSI/ESD SP17.1 was submitted to IEC as PAS and as IEC 61340-5-6 as Technical Specification, review of national committees of IEC and outcome of IEC meeting in June 2022 will be discussed in September ESDA meeting series.

-

The working group agreed to develop a slide set to introduce ANSI/ESD SP17.1 and give guidance on how the methodology described in the document can be applied to typical assessment tasks. The working group reviewed a work statement for a new standard practice, ESD SP17.2, on process assessment of electrical disturbances. The work statement will be submitted to TAS for review and approval. The group discussed technical topics to include in the next revision of ANSI/ESD SP17.1 The group also discussed what content from ANSI/ESD SP10.1 will be moved to ANSI/ESD SP17.1 in the next revision. The group is working on a new technical report ESD TR17.0-02.

-

The working group decided to include the resistance measurements from ANSI/ESD SP10.1 - Automated Handling Equipment in the next version of ANSI/ESD SP17.1. Additional technical topics to add to the next revision was also discussed including possible adding a report template for process assessment. A new technical report will be created on measurement of CDM-related ESD characteristics within an automated process or equipment. A new standard practice will be developed on EMI/EOS process assessment.

-

The working group discussed updates and additions to the next revision of ANSI/ESD SP17.1. EMI and EOS topics will be addressed in a new document. A writing team has been established for revising ANSI/ESD SP10.1. Resistance measurements from ANSI/ESD SP10.1 - Automated Handling Equipment will be included in the next version of ANSI/ESD SP17.1. Charge accumulation measurements will remain in the next version of ANSI/ESD SP10.1. A writing team proposed a new TR on measuring CDM-related ESD characteristics within an automated process or equipment based on recent technical presentations and work.

-

Summary of meeting activities:

The working group decided on next steps and some content updates and additions to the next revision of ANSI/ESD SP17.1. Writing Teams were established to merge ANSI/ESD SP10.1 “Automated Handling Equipment” in the next revision of ANSI/ESD SP17.1 and complete the development on a new document on measurement of CDM-related ESD characteristics within an automated process or equipment”.